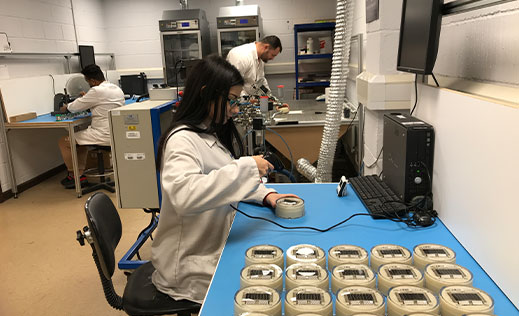

As part of our strategy to offer a one stop shop more and more of our Customers ask us to undertake assembly of the final product which we do with a bespoke Flow Line assembly and Cellular Manufacturing techniques.

We recognise the trust that our customers place in ADAPT and we ensure that all staff involved in any final assembly product are not only highly trained in the appropriate assembly techniques but have a meticulous attention detail so we are able to ensure quality is built into every product at every step.

Depending upon the levels of traceability required we are able to maintain full traceability of components and operator activity, through component/product serialisation and our manufacturing system controls.

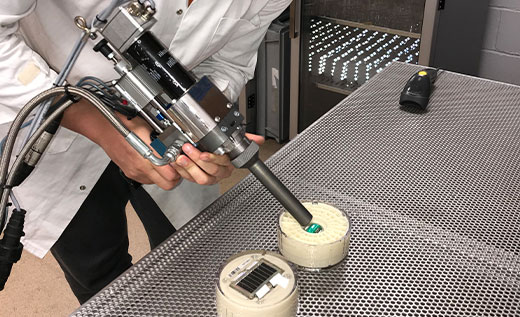

ADAPT also offer product potting service and have a considerable amount of experience in potting products that are installed in harsh environments.

Potting is a very unforgiving process so it is essential that maximum effort has been put into design for manufacture (DFM) and design for test (DFT) with ADAPTs team. Process control is also absolutely critical and we have a number bespoke potting systems designed specifically for the task.

Where product or customer requirements dictate a controlled environment then we are able to offer a dedicated manufacturing suite;

An important part of Final Product Assembly of course is the management of the supply chain of custom “drawn” parts including; painted metal parts; injection moulded plastic parts; custom facias; screen printed glass; overlays and LCDs and of course not forgetting the product packaging.

We have a huge level of experience in sourcing all these parts and work closely with our supply chain and customers to define the appropriate quality standards and then ensure these are maintained through supplier collaboration and rigorous goods-in Inspection.

END-TO-END MANUFACTURING

Prototype To Production

100% Quality And Reliability

Technical Manufacturing Expertise

Collaborative Working

Case Studies