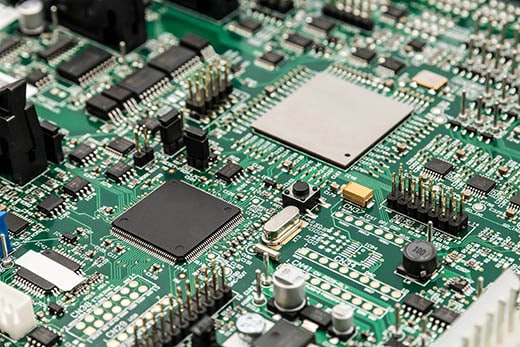

Across ADAPTs two manufacturing sites we boast 6 SMT lines comprising of Mydata and IPulse placement machines. This gives a huge amount of capacity and flexibility to cope with both prototyping and volume production requirements.

We have both standard hot air reflow and Vapour Phase reflow ovens so there is no need to compromise on product quality due to process restrictions. Whilst our hot air reflow ovens are extremely capable there are some jobs that due to their design (usually where there is a high thermal mass as a result of heavy copper layers and/or extremely large components) where Vapour Phase is really the only option. Both Hitchin and St.Neots have both processes.

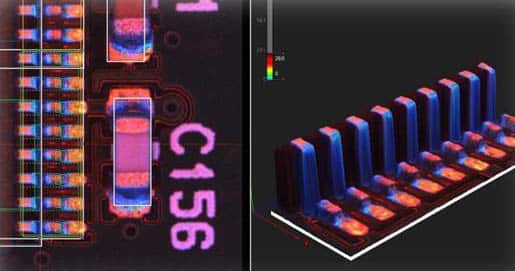

We also have in line 3D inspection processes covering both Solder Paste Inspection (SPI) and Component Automatic Optical Inspection (AOI).

These are extremely powerful inspection tools ensuring that the whole SMT process remains within limits for the duration of each assembly run.

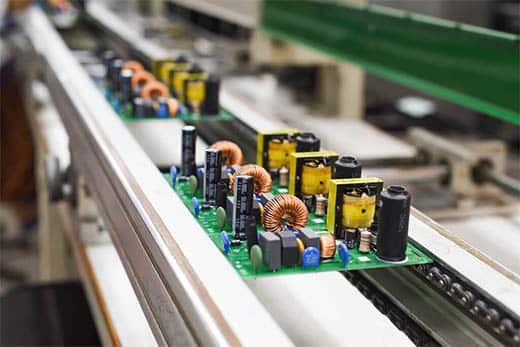

Not withstanding the fact that SMT technology covers the vast majority of the boards we manufacture nearly all boards have some “conventional” through hole components. Plus some boards we make are solely designed around through-hole technology.

We process these assemblies utilising flow line assembly techniques with hand soldering, flow soldering and selective soldering as appropriate. Other equipment includes cut and clinch machines, cropping machines, pinning machine and presses for press-fit connectors.

All workmanship is to IPC- 610 class 2 or 3 standards as required.

END-TO-END MANUFACTURING

Prototype To Production

100% Quality And Reliability

Technical Manufacturing Expertise

Collaborative Working

Case Studies